Climate change has become a pressing issue in recent years, with industries worldwide seeking innovative ways to reduce their carbon footprint. One such industry is cement production, notorious for its significant contribution to global carbon dioxide emissions. However, a breakthrough discovery offers a glimmer of hope in the quest for sustainability.

The Carbon Conundrum

Cement manufacturing currently accounts for about 8 percent of total CO2 emissions globally, ranking as the fourth-largest emitter worldwide. The traditional process involves mining raw materials from various sources like mountains, riverbeds, and the ocean floor. This extraction process releases copious amounts of carbon into the atmosphere.

A Green Solution Emerges

In a bid to revolutionize cement production and combat climate change, researchers at Northwestern University teamed up with Cemex’s innovation development branch in Switzerland. Together, they devised an ingenious method that could potentially transform cement from being a carbon source to a carbon sink.

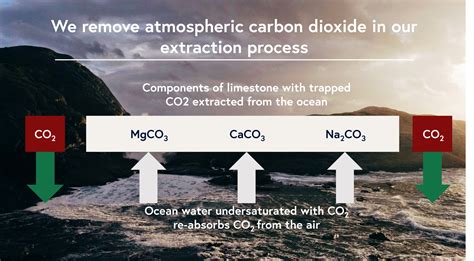

The key lies in seawater electrolysis – a groundbreaking technique that uses electricity to split seawater molecules. This process not only generates hydrogen gas and chlorine gas but also produces essential minerals like calcium carbonate, the primary ingredient used in cement manufacturing.

From Annoyance to Advantage

While conventional wisdom views precipitated minerals from electrolysis as an impediment due to equipment cluttering, researchers have flipped the script. These minerals could hold the key to sustainable cement production by offsetting carbon emissions.

The team conducted experiments to optimize mineral formation during electrolysis by adjusting voltage levels and introducing controlled amounts of carbon dioxide into seawater. Through these manipulations, they were able to modify the properties of precipitating minerals, paving the way for tailored construction materials with varying densities and structures.

A Brighter Future

The implications of this research extend beyond just cement production; it opens doors to creating an array of carbon-stashing products like paint, plaster, and concrete using sustainable methods. By harnessing renewable energy sources for electricity during this process, these materials could potentially become not just carbon-neutral but actively sequester atmospheric CO2 for thousands of years.

As we stand at a pivotal moment in history concerning climate change mitigation efforts, supporting scientific advancements like these is more crucial than ever before. Embracing sustainable practices in industries such as cement production can steer us towards a greener future with reduced environmental impact.

Amidst mounting global concerns about our planet’s health and well-being, initiatives like seawater splitting offer promising solutions that could pave the way towards a more sustainable tomorrow.